Holograms Drive Diesel Engine Aftermarket Parts’ Authentication

13 Sep 2022 | Press Release

Counterfeit components are a big problem for diesel engine OEMs and aftermarket parts suppliers. Dr Paul Dunn, chair of the International Hologram Manufacturers Association, considers the role commercial holograms can play in protecting brands and profits.

The exact cost of global counterfeiting is unknown but it is estimated to impact on the diesel aftermarket parts market to the tune of hundreds of millions of dollars a year in lost revenue. Furthermore, the damage caused to brand reputation, loss of sales and market capitalisation by fake components is incalculable.

Sophisticated reproductions of original parts have made it incredibly hard for even the trained eye to distinguish real from fake, while illegal imitations of diesel engine components, oils and lubricants manufactured from inferior materials can endanger life because they are not tested to the same rigorous industry standards as bonafide manufacturers have to observe and can often fail at critical moments.

Over extended global supply chains, poor regional law enforcement, pitiful financial penalties, the growth of the internet as a conduit for distributing counterfeit goods, the rise of brand power and the impact of advanced reprographic technology which has made it easy and affordable to copy brand packaging, have all been cited as contributing to increased levels of counterfeiting.

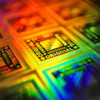

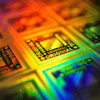

The development of holograms and other security devices, whose effects cannot be completely replicated or simulated by normal reprographics methods, followed the emergence of high-quality copying methods and the ability to reproduce accurate copies of documents, labels and packaging. Today, the technology is used in a wide variety of formats such as tamper-evident labels and seals on packaging, offering effective brand protection through the innovative evolution of techniques designed to create easily recognised, yet hard to copy layered authentication devices.

Authentication

This has often occurred in combination with other authentication technologies where holograms provide overt first line authentication while covert features such as scrambled images, microtext, UV sensitive or other specialist inks provide a second line of defence for trained examiners equipped with appropriate decoding equipment. Additionally, data matrix, QR codes or other serialisation methods are all now be incorporated in to holograms to provide enhanced track and trace benefits.

Modern authentication holograms feature a host of intrinsic techniques and visual effects that make them impossible to copy 100% – the product and packaging under protection may have been counterfeited, but a poorly copied hologram is more often than not the tell-tale give-away that all is not what it seems. Effectively, the hologram acts as an alarm bell, alerting people to the possibility that the product could be a counterfeit. In other words, the role of a hologram is not to prevent counterfeits; rather to act as an effective detection device, making it easier for the trained eye to distinguish the real product from a fake one.

Anti-counterfeiting programmes in the diesel engine components and aftermarket show that it is not necessarily the sole responsibility of the customer to examine a hologram to check its validity. The onus is on manufacturers and enforcement agencies to prevent fakes penetrating the supply chain in the first place, which is why effective brand protection programmes involve formal examination and inspection systems throughout the distribution network. Sector leading manufacturers have seen the value of this and it’s one of the reasons why they are including holograms as integral parts of their authentication strategies.

For instance, Cummins Inc. has a hologram protection labelling project in one of its global regions to protect its components and spare parts supply chain, enabling customers to distinguish genuine products from counterfeit. Cummins is applying its original part number labels to all components supplied in this region, including the additional hologram protection labels. Various properties of the transparent hologram integrated into a printed base label, the presence of slots along the edges and a QR-code enable the customer to verify that a part is genuine.

Cummins’ Stamford AC generators also carry a hologram and unique machine reference number to enable both visual authentication and online verification of genuine items. The hologram, made using Du Pont’s photopolymer, features red and green colours and when tilted forwards, reveals three white spots above the word ‘Stamford’. Similarly, when titled backwards, four white spots could be seen underneath the word.

Worldwide applications

Another brand, Bosch, has adopted holographic technology to authentic its products used on diesel engines and diesel fuel injection systems. Secure code labels attached to product packaging feature hologram technology are extremely difficult to copy. An 18-digit secure code is unique to every product and the last six characters are repeated individually in the hologram. When viewed, the code and logo glimmer in rainbow colours when exposed to direct light. In indirect light however, only black and silvery structures can be seen. The customer then visits a dedicated website link and enters the code for verification.

In the USA, another manufacturer of engine overhaul kits, engine bearings, liners, connecting rods, gaskets and gasket sets, valves and valve train components, camshafts, oil pumps, turbocharger components and fuel system parts uses holographic labels affixed to packaging to ensure quick and accurate product authentication.

Perkins Engines has also seen the value in the supply chain, using tamper evident hologram seals to protect and secure the authentication of its after sales parts. The British diesel engine company has been applying holograms on its packaging many years as part of its ongoing brand protection strategy, supported by an end-user education campaign in international territories most prone to counterfeiting activity and backed by the hologram supplier, OpSec.

Holograms used in these applications will help to protect brands’ customers and end-users from worrying safety, quality and reliability issues surrounding illegally produced counterfeit products. Innovation in this form can help also to remove the financial risks associated with the counterfeiters’ use of sub-standard materials and tolerances leading to shortened equipment life, higher running costs and potential threat to life through fire or catastrophic equipment failure.

The use of well-designed and properly deployed authentication solutions, as advocated by the ISO12931 standard, enables those with law enforcement responsibility to verify the authenticity of a legitimate product, differentiating it from fake products coming from counterfeiting hot spots in Asia and eastern Europe. Even those that carry a ‘fake’ authentication feature can be distinguished from the genuine item if that item carries a carefully thought-out authentication solution.

Moving forward, holography’s capacity to absorb other data forms and product tracking information is important. For now, however, the technology continues to demonstrate an ability to deter counterfeiting and play a critical part in the on-going battle to stay one step of ahead of the counterfeiters and criminals.